Product

- ALL

- Insulation Gasket Kit

- MECHANICAL SEAL

- PTFE SERIES

- Expanded PTFE

- Modified PTFE

- Filled PTFE

- CNC PTFE Parts

- COMPRESSED FIBRE SHEET

- GRAPHITE GASKET SHEET

- GLAND PACKING & TOOLS

- PTFE Series Packing

- Aramid/Kevlar Series Packing

- Synthetic Fiber Series Packing

- Carbon Fiber Series Packing

- Graphite Series Packing

- Plant Fiber Series Packing

- JOINT GASKET

- Spiral Wound Gaskets

- Cammprofile Gasket

- Jacketed Gaskets

- Ring Joint Gasket

- PTFE Bonded EPDM Gasket

- PTFE Envelope Gasket

- Disc Spring

Spiral Wound Gasket

2019-09-06

PTFE Bonded EPDM Gasket

2019-10-24PTFE Envelope Gasket

Material: PTFE , Non-asbestos, EPDM, Metal

PTFE Envelope gaskets have three structure PMF, PMS, PFT and PFF. Gaskets are manufactured by gasket core with a PTFE lamination. They combine the mechanical strength, resilience and bolt load retention of gasket with the chemical resistance of PTFE. They are used in equipment with glass; ceramic or glass coated steel flanges. Maximum service temperature is 500oF (260oC), the limit for PTFE.

PTFE Envelope Gasket

Material: PTFE , Non-asbestos, EPDM, Metal

PTFE Envelope gaskets have three structure PMF, PMS, PFT and PFF. Gaskets are manufactured by gasket core with a PTFE lamination. They combine the mechanical strength, resilience and bolt load retention of gasket with the chemical resistance of PTFE. They are used in equipment with glass; ceramic or glass coated steel flanges. Maximum service temperature is 500oF (260oC), the limit for PTFE.

PTFE lamination thickness usually 0.5 mm. Open externally or internally, inside which are allocated non-asbestos gasket material. PTFE lamination has excellent resistance acids, protecting the insert, leaving no residue on the body flange, and having excellent dielectric characteristics and a low porosity. They can also be coupled always inside the casing, a corrugated ring of metal material to increase the sealing capacity in the most difficult conditions. The latter may in turn be provided with a special fin the grounding to discharge any static electricity.

Recommended applications:

Flanges, tanks, reactors, stainless steel and especially between enamel surfaces. This gasket has excellent anti-corrosive property, widely using in chemical, petrochemical and pharmaceutical industries.

|

|

PMF |

PMS |

|

PFT |

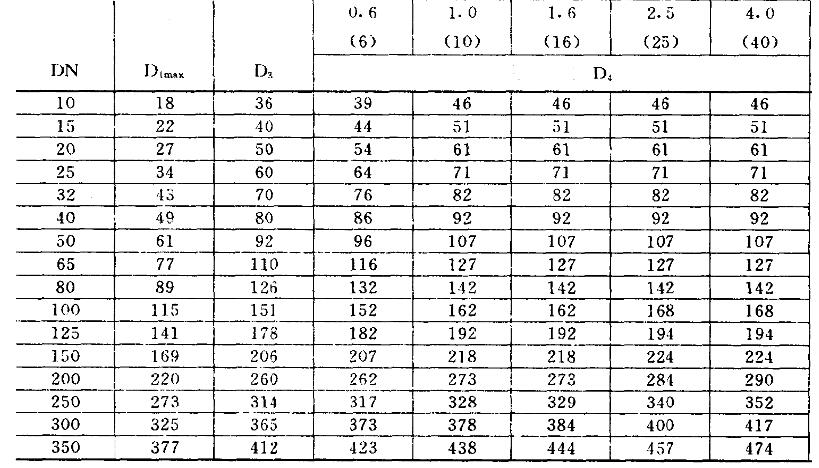

Gasket Size:

PMF |

|

PMS |

|

PFT |

|

Gasket Size Tolerance: