Product

- ALL

- Insulation Gasket Kit

- MECHANICAL SEAL

- PTFE SERIES

- Expanded PTFE

- Modified PTFE

- Filled PTFE

- CNC PTFE Parts

- COMPRESSED FIBRE SHEET

- GRAPHITE GASKET SHEET

- GLAND PACKING & TOOLS

- PTFE Series Packing

- Aramid/Kevlar Series Packing

- Synthetic Fiber Series Packing

- Carbon Fiber Series Packing

- Graphite Series Packing

- Plant Fiber Series Packing

- JOINT GASKET

- Spiral Wound Gaskets

- Cammprofile Gasket

- Jacketed Gaskets

- Ring Joint Gasket

- PTFE Bonded EPDM Gasket

- PTFE Envelope Gasket

- Disc Spring

Die Formed Graphite Ring

2019-06-28

Cammprofile Gasket

2019-06-28Jacketed Gasket

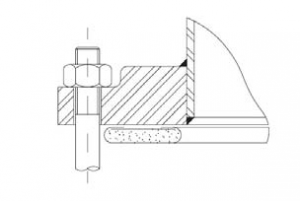

Jacketed gaskets are produced in a wide variety of different materials (in various combinations), in many cross-sections and in many styles. They are suitable for flanges in heat exchangers, pipe flanges, boilers and process equipment.

• Metallic outer shell with asbestos free filler

• The filler material gives the gasket resilience

• The metal jacket protects the filler and resists pressures, temperatures and corrosion

Jacketed gaskets consist of a soft filler encapsulated in a metallic material. The filler material provides the gasket with compressibility and resilience while the jacket provides compressive strength and blow out resistance. Metal jacketed gaskets can withstand over 30% deviation from nominal thickness, which is welcome in cases of imperfect flat flange surfaces. Metal jacketed gaskets can be produced in a variety of shapes, making them ideal for heat exchanger applications. A wide range of jacket and filler materials is available to suit every service condition. Bars can be integrated or welded into the gasket. The minimum radius between the bars and internal diameter is 8mm for gaskets with integrated bars, while there is no limit for gaskets with welded bars. Metal jacketed gaskets are available in different shapes such as circular, oval, rectangular or any other shape.

Materials of constructionInner gasket materials:

|

Basic Structure |